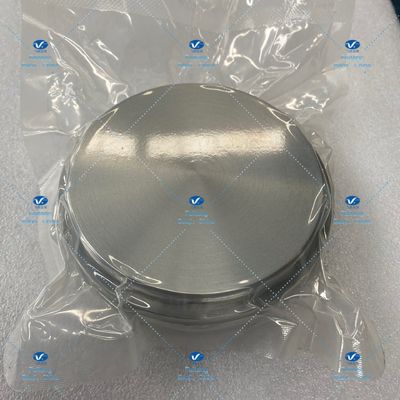

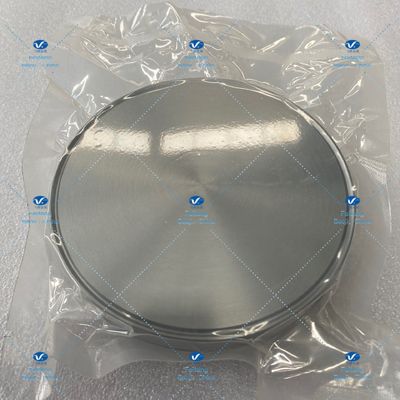

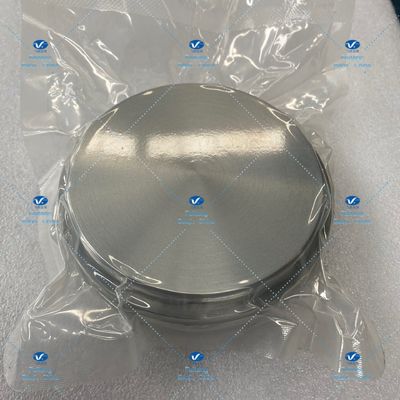

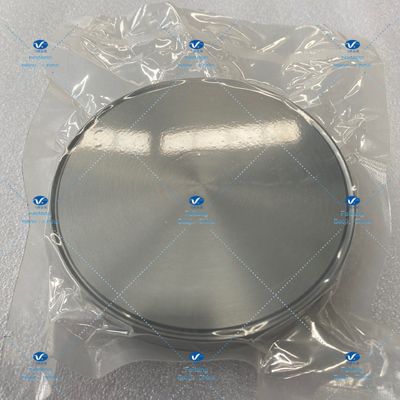

High Resilience Sputtering Titanium Targets OD153*11

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

| Model Number | Titanium target |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

| Product Name | Titanium Target | Standard | Gr2 |

|---|---|---|---|

| Grade | Titanium | Certifaction | GB/T19001-2016 Idt ISO9001:2015 GJB9001C-2017 |

| Customized | Customized | Packaging | Vacuum Package In Wooden Case |

| Shape | Round | Port Of Delivery | Xi'an Port, Beijing Port, Shanghai Port, Guangzhou Port, Shenzhen Port |

| Highlight | Titanium Targets OD153,11mm Medical Field Titanium Targets,Ti High Resilience Sputtering Targets |

||

Titanium target Gr2 ASTM B381-06 a OD153*11 Sputtering Target Sputtering Materials Target Sputtering

| Item Name | Titanium target |

| Grade | Gr2 |

| Material | Titanium |

| Packaging | Vacuum package in wooden case |

| Port of delivery |

Xi'an port, Beijing port, Shanghai port, Guangzhou port, Shenzhen port |

| Shape | Round. |

| Surface | Pickled, Polished |

Benefits:

1. Low Density and High Specification Strength

2. Excellent Corrosion Resistance

3. Good Resistance to Effect of Heat

4. Excellent Bearing to Cryogenics Property

5. Nonmagnetic and Non-toxic

6. Good Thermal Properties

7. Low Modulus of Elasticity

Titanium is a very active metal, its equilibrium potential is very low, in the medium of thermodynamic corrosion tendency. But in fact, titanium is very stable in many media, such as titanium in oxidizing, neutral and weak reducing media is corrosion resistant. This is because titanium and oxygen have a great affinity, in the air or oxygen-containing medium, titanium surface generates a dense, strong adhesion, large inert oxide film, which protects the titanium matrix from corrosion. It quickly heals or regenerates itself even from mechanical wear. This indicates that titanium is a metal with a strong passivation tendency. The oxide film of titanium always maintains this characteristic when the medium temperature is below 315℃. In order to improve the corrosion resistance of titanium, surface treatment technologies such as oxidation, electroplating, plasma spraying, ion nitride, ion implantation and laser treatment were developed, which enhanced the protective effect of titanium oxide film and obtained the desired corrosion resistance effect. A series of corrosion resistant titanium alloys such as titanium-molybdenum, titanium-palladium and titanium-molybdenum-nickel have been developed to meet the needs of metal materials in the production of sulfuric acid, hydrochloric acid, methyl amine solution, high temperature wet chlorine gas and high temperature chloride. The application of titanium-32 molybdenum alloy in titanium castings, titanium-0.3 molybdenum-0.8 nickel alloy in the environment where crevices or pitting corrosion often occur, or titanium-0.2 palladium alloy in the local area of titanium equipment have obtained good application results. The new titanium alloy can be used for a long time at 600℃ or higher. Compared with steel and copper, titanium has the longest vibration attenuation time after being subjected to mechanical vibration and electrical vibration. Titanium can be used as tuning fork, vibration element of medical ultrasonic crusher and vibration film of advanced audio speakers. Titanium is a non-magnetic metal that will not be magnetized in a large magnetic field. It is non-toxic and has a good compatibility with human tissues and blood, so it is used in the medical field. This property of titanium indicates its high yield strength ratio (tensile strength/yield strength) and poor plastic deformation during forming. Due to the high ratio of yield limit to elastic modulus of titanium, the resilience of titanium is high. Although the thermal conductivity of titanium is lower than that of carbon steel and copper, the wall thickness of titanium can be greatly reduced due to its excellent corrosion resistance, and the heat transfer mode between the surface and steam is drop-shaped condensation, which reduces the heat group. The thermal resistance of titanium can also be reduced without scaling on the surface, which significantly improves the heat transfer performance of titanium.

![]()