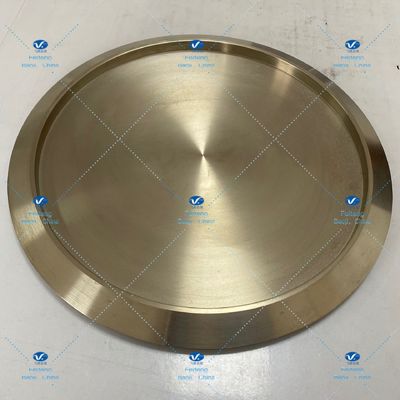

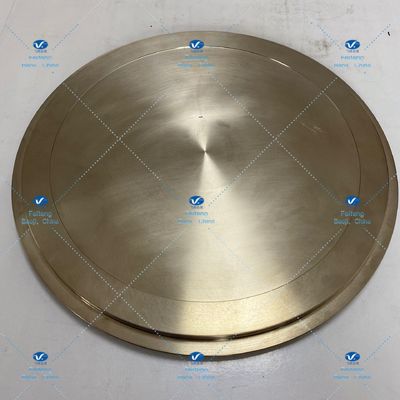

OD380*23mm Nonmagnetic Non Toxic Titanium Targets

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

| Model Number | Titanium target |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Product Name | Titanium Target | Standard | Gr2 |

|---|---|---|---|

| Grade | Titanium | Certifaction | GB/T19001-2016 Idt ISO9001:2015 GJB9001C-2017 |

| Customized | Customized | Packaging | Vacuum Package In Wooden Case |

| Shape | Round | Port Of Delivery | Xi'an Port, Beijing Port, Shanghai Port, Guangzhou Port, Shenzhen Port |

| Highlight | Nonmagnetic Non Toxic Titanium Targets,23mm Nonmagnetic Titanium Targets,OD380 titanium target |

||

Titanium target Gr2 ASTM B381-06 a OD380*23 Sputtering Target Sputtering Materials Target Sputtering

| Item Name | Titanium target |

| Grade | Gr2 |

| Material | Titanium |

| Packaging | Vacuum package in wooden case |

| Port of delivery |

Xi'an port, Beijing port, Shanghai port, Guangzhou port, Shenzhen port |

| Shape | Round. |

| Surface | Pickled, Polished |

The coating target is a sputtering source that forms various functional films on the substrate by magnetron sputtering, multi-arc ion plating or other types of coating systems under appropriate technological conditions. To put it simply, the target material is the target material of high-speed charged particles bombardment. When used in high-energy laser weapons, different power densities, different output waveforms and different wavelengths of laser interact with different targets, different killing and destruction effects will be produced. For example, evaporative magnetron sputtering coating is heated evaporation coating, aluminum film, etc. Change different target material (such as aluminum, copper, stainless steel, titanium, nickel target, etc.), can get different film system (such as super hard, wear resistant, corrosion resistant alloy film, etc.).

Compared with wet coating technology, vacuum coating technology has the following advantages:

(1) thin films and substrates have wide selection of materials, and film thickness can be controlled to prepare functional films with various functions.

(2) to prepare thin films under vacuum, clean environment, and thin films are not easily contaminated. Therefore, films with good densification, high purity and uniform coating can be obtained.

(3) the bonding strength between the film and the substrate is good and the film is firm.

(4) dry coating does not produce waste liquid or environmental pollution.

Vacuum coating technology mainly includes vacuum evaporation, vacuum sputtering, vacuum ion plating, vacuum beam deposition, chemical vapor deposition and so on. In addition to chemical vapor deposition, other methods have the following common characteristics:

(1) all kinds of coating technologies require a specific vacuum environment to ensure the movement of the vapor molecules formed in the process of heating evaporation or sputtering, not to be hit, blocked and interfered by a large number of gas molecules in the atmosphere, and to eliminate the harmful effects of impurities in the atmosphere.

(2) all coating technologies require a source or target to convert the materials of evaporation film into gas. Due to the continuous improvement of source or target, the selection range of film making materials has been greatly expanded. Metal, metal alloys, intermetallic compounds, ceramics or organic materials can be evaporated with various metal films and dielectric films, and can also be obtained by evaporating different materials at the same time.

(3) the evaporating or sputtered film making materials can be accurately measured and controlled in the process of forming thin films with the workpiece to be plated, so as to ensure the uniformity of the film thickness.

(4) each film can accurately control the composition and mass fraction of residual gas in the coating chamber by means of a fine adjustment valve, thereby preventing the oxidation of the evaporating material, reducing the mass fraction of oxygen to a minimum and filling inert gas, which is impossible for wet coating.

(5) due to the continuous improvement of the coating equipment, the coating process can be realized continuously, thereby greatly improving the output of the product and no pollution to the environment during the production process.

(6) because the film is made in vacuum, the purity of the film is high, the density is good, and the surface is bright without processing. This makes the mechanical and chemical properties of the film better than that of the electrodeposited film and the chemical film.

1. Low Density and High Specification Strength

2. Excellent Corrosion Resistance

3. Good Resistance to Effect of Heat

4. Excellent Bearing to Cryogenics Property

5. Nonmagnetic and Non-toxic

6. Good Thermal Properties

7. Low Modulus of Elasticity