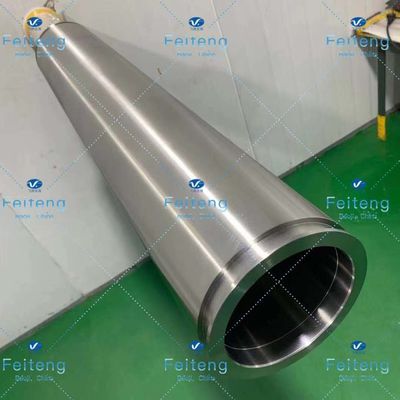

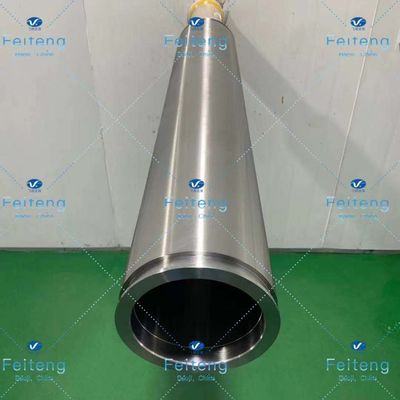

Chromium Stainless Steel Tube Target 155OD*125ID*888L

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

| Model Number | Stainless Steel Tube Target |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Vacuum package in wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Packaging | Vaccum Package | Certification | GB/T19001-2016 Idt ISO9001:2015 MANAGEMENT SYSTEM CNAS C034-M |

|---|---|---|---|

| Model Number | Stainless Steel Tube Target | Size | φ155*φ125*888 |

| Material | Stainless Steel | Place Of Origin | Baoji, Shaanxi, China |

| Brand Name | Feiteng | ||

| Highlight | Stainless Steel Tube Target 155mm,Stainless Steel Tube Target 125mm,Chromium Tube Target 888L |

||

Stainless Steel Tube Target 155OD*125ID*888L

| Product | Stainless Steel Tube Target |

| Size | φ155*φ125*888 |

| Packaging | Vacuum package in wooden case |

| Port of delivery | Xi'an port, Beijing port, Shanghai port, Guangzhou port, Shenzhen port |

Stainless steel is often divided into: martensitic steel, ferrite steel, austenitic steel, austenitic - ferrite (duplex) stainless steel and precipitation hardening stainless steel. In addition, can be divided into: chromium stainless steel, chromium nickel stainless steel and chromium manganese nitrogen stainless steel. And special stainless steel for pressure vessels.

Heat resistant performance

Heat resistance refers to the high temperature stainless steel can still maintain its excellent physical and mechanical properties.

Influence of carbon: Carbon is an element that strongly forms and stabilizes austenite and enlarges the austenite zone in austenitic stainless steel. The ability of carbon to form austenite is about 30 times that of nickel. Carbon is a interstitial element, and the strength of austenitic stainless steel can be significantly improved by solution strengthening. Carbon also improves the stress and corrosion resistance of austenitic stainless steel in high concentration chloride (e.g. 42%MgCl2 boiling solution).

But, in the austenitic stainless steel, carbon is often seen as the harmful elements, this is mainly due to the corrosion of stainless steel used in some conditions, such as welding or heating by 450 ~ 850 ℃), carbon steel with chromium in forming high chromium Cr23C6 type carbon compounds which can lead to local chromium depletion, make steel corrosion resistance especially resistant to intergranular corrosion performance degradation. So. Since the 60 s of the development of new cr-ni austenitic stainless steel is mostly carbon content less than 0.03% or 0.02% of the ultra-low carbon type, you can know as the carbon content is reduced, the steel intergranular corrosion sensitivity is reduced, when carbon content less than 0.02% is one of the most obvious effect, some experiments also pointed out that the carbon will also increase the chromium austenitic stainless steel corrosion tendency. Due to the harmful effects of carbon, not only in the process of austenitic stainless steel smelting should be as low as possible according to the requirements of the control of carbon content, but also in the subsequent hot and cold processing and heat treatment process to prevent the surface of stainless steel carburization, to avoid chromium carbide precipitation.

Corrosion resistance

When the amount of chromium atom in steel is not less than 12.5%, the electrode potential of steel will change from negative potential to positive electrode potential. Prevent electrochemical corrosion.

Advantages:

1, high conductivity

2. Good thermal conductivity

3, good weldability

4, excellent plasticity and ductility

5, excellent cold working performance

6. Customized according to the drawings required by customers