1Cr18Ni9 0Cr19Ni9 Stainless Steel Tube Target 18% Chromium 8% Nickel

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

| Model Number | Stainless Steel Tube Target |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Vacuum package in wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

| Packaging | Vaccum Package | Certification | GB/T19001-2016 Idt ISO9001:2015 MANAGEMENT SYSTEM CNAS C034-M |

|---|---|---|---|

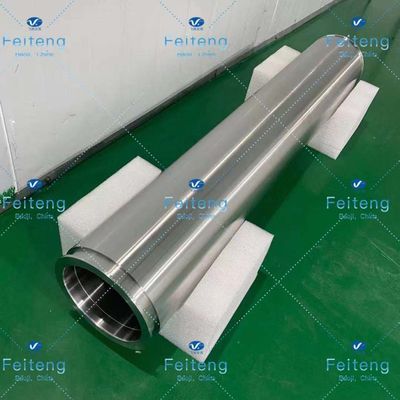

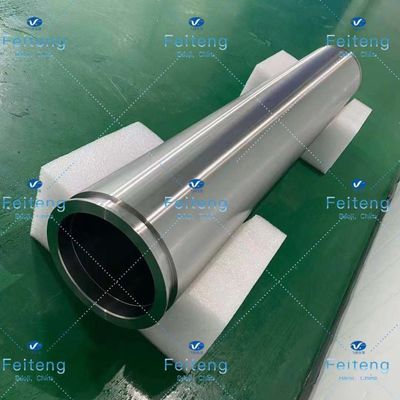

| Model Number | Stainless Steel Tube Target | Size | φ155*φ125*888 |

| Material | Stainless Steel | Place Of Origin | Baoji, Shaanxi, China |

| Brand Name | Feiteng | ||

| Highlight | 0Cr19Ni9 Tube Target,1Cr18Ni9 Tube Target,18% Chromium 8% nickel target |

||

Stainless Steel Tube Target 155OD*125ID*888L

| Product | Stainless Steel Tube Target |

| Size | φ155*φ125*888 |

| Packaging | Vacuum package in wooden case |

| Port of delivery | Xi'an port, Beijing port, Shanghai port, Guangzhou port, Shenzhen port |

Stainless steel is often divided into: martensitic steel, ferrite steel, austenitic steel, austenitic - ferrite (duplex) stainless steel and precipitation hardening stainless steel. In addition, can be divided into: chromium stainless steel, chromium nickel stainless steel and chromium manganese nitrogen stainless steel. And special stainless steel for pressure vessels.

Austenitic stainless steel

It contains more than 18% chromium, 8% nickel and a small amount of molybdenum, titanium, nitrogen and other elements. Good comprehensive performance, can resist the corrosion of a variety of media. Austenitic stainless steel commonly used grades are 1Cr18Ni9, 0Cr19Ni9, etc. 0 cr19ni9 steel Wc< 0.08%, marked as "0" in the steel number. This type of steel contains large amounts of Ni and Cr, making the steel austenitic at room temperature. This kind of steel has good plasticity and toughness, weldability and corrosion resistance and non-magnetic or weak magnetic, the corrosion resistance in oxidizing and reducing medium are good, used to make acid equipment, such as corrosion resistant containers and equipment lining, pipelines, nitric acid resistant equipment parts, etc., also can be used as the main body of watches and clocks jewelry stainless steel material. Austenitic stainless steel generally adopts solution treatment, that is, the steel is heated to 1050 ~ 1150℃, and then water cooling or air cooling, in order to obtain the single-phase austenite structure.

Austenitic ferrite duplex stainless steel

It has the advantages of austenitic and ferritic stainless steel, and has superplasticity. Austenitic and ferrite structures each account for about half of stainless steel. In the case of low carbon content, the content of Chromium (Cr) is between 18% and 28%, and the content of nickel (Ni) is between 3% and 10%. Some steels also contain Mo, Cu, Si, Nb, Ti, N and other alloying elements. This kind of steel has the characteristics of austenitic and ferritic stainless steel, compared with ferrite, higher plasticity, toughness, no brittleness at room temperature, intergranular corrosion resistance and welding performance are significantly improved, but also maintain the 475℃ brittleness of ferritic stainless steel and high thermal conductivity, with superplastic characteristics. Compared with austenitic stainless steel, it has higher strength and resistance to intergranular corrosion and chloride stress corrosion. Duplex stainless steel has excellent corrosion resistance and is also a nickel-saving stainless steel.

Advantages:

1, high conductivity

2. Good thermal conductivity

3, good weldability

4, excellent plasticity and ductility

5, excellent cold working performance

6. Customized according to the drawings required by customers