Corrosion Resistance Ferrite Stainless Steel Targets Tube Shaped ISO9001

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

| Model Number | Stainless Steel Tube Target |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Vacuum package in wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Packaging | Vaccum Package | Certification | GB/T19001-2016 Idt ISO9001:2015 MANAGEMENT SYSTEM CNAS C034-M |

|---|---|---|---|

| Model Number | Stainless Steel Tube Target | Size | φ155*φ125*888 |

| Material | Stainless Steel | Place Of Origin | Baoji, Shaanxi, China |

| Brand Name | Feiteng | ||

| Highlight | Ferrite Stainless Steel Targets ISO9001,Stainless Steel Targets Tube Shaped,Corrosion Resistance Ferrite Tube Targets |

||

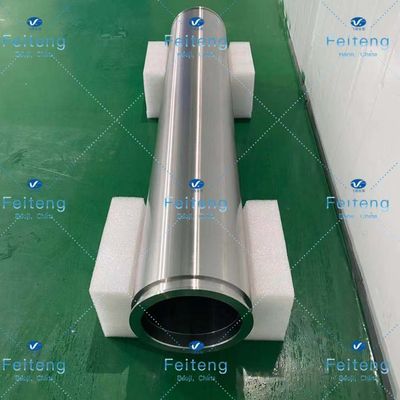

Stainless Steel Tube Target 155OD*125ID*888L

| Product | Stainless Steel Tube Target |

| Size | φ155*φ125*888 |

| Packaging | Vacuum package in wooden case |

| Port of delivery | Xi'an port, Beijing port, Shanghai port, Guangzhou port, Shenzhen port |

Stainless steel is often divided into: martensitic steel, ferrite steel, austenitic steel, austenitic - ferrite (duplex) stainless steel and precipitation hardening stainless steel. In addition, can be divided into: chromium stainless steel, chromium nickel stainless steel and chromium manganese nitrogen stainless steel. And special stainless steel for pressure vessels.

weldability

The requirements for welding performance are also different for different product uses. A class of tableware on welding performance generally do not require, even including some pot enterprises. But the vast majority of products require good welding performance of raw materials, such as second-class tableware, thermos cups, steel pipes, water heaters, drinking machines and so on.

Corrosion resistance

The vast majority of stainless steel products for corrosion resistant performance is good, like a, 2 kinds of tableware, kitchen utensils and appliances, water heaters, water dispensers, etc., some foreign businessmen on corrosion resistance of products also do experiment: in NACL aqueous solution heated to boiling, after a period of time out solution, wash and drying, weight loss, to determine the degree of corrosion (note: When the product is polished, Fe content in the emery cloth or sandpaper will lead to rust spots on the surface of the test.)

Polishing performance

Stainless steel products in today's society are generally polished when the production of this process, only a few products such as water heater, water dispener liner, do not need to be polished. So this requires that the polishing performance of raw materials is very good. The main factors affecting the polishing performance are as follows:

Surface defects of raw materials. Such as scratches, pitting, pickling and so on.

② The problem of raw materials. The hardness is too low, it is not easy to shine when polishing (BQ is not good), and the hardness is too low, it is easy to appear orange peel phenomenon on the surface when deep drawing, thus affecting BQ. BQ with high hardness is relatively good.

(3) After deep drawing, small black spots and RIDGING will appear on the surface of the products with great deformation, thus affecting the BQ property.

Advantages:

1, high conductivity

2. Good thermal conductivity

3, good weldability

4, excellent plasticity and ductility

5, excellent cold working performance

6. Customized according to the drawings required by customers