ISO9001 Corrosion Resistant Grade 2 Titanium Castings

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

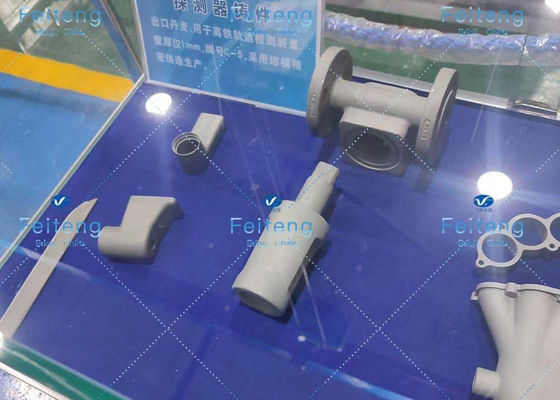

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

| Model Number | Titanium Casting |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Brand Name | Feiteng | Model Number | Titanium Casting |

|---|---|---|---|

| Certification | GB/T19001-2016 Idt ISO9001:2015 MANAGEMENT SYSTEM CNAS C034-M | Place Of Origin | Baoji, Shaanxi, China |

| Packaging | Wooden Case | ||

| Highlight | Grade 2 Titanium Castings,Corrosion Resistant Titanium Castings,ISO9001 Gr2 Titanium Casting |

||

Titanium Casting ASTM B367 Gr2 Titanium Castings Titanium MateriaI

| Name | Titanium Casting |

| Grade | Gr2 |

| Material | Titanium |

| Standard | ASTM B367 |

| Packaging | Wooden case |

| Delivery |

Xi'an port, Beijing port, Shanghai port, Guangzhou port, Shenzhen port |

In seawater, titanium has incomparable corrosion resistance, especially the high speed erosion corrosion of seawater. At present, many countries have developed a variety of advanced titanium submersible, submarine, submarine laboratory equipment to carry out Marine research. In addition, titanium equipment and devices are widely used in coastal power stations, offshore oil production equipment, seawater desalination, Marine chemical production and mariculture. Titanium's lightweight, high-strength properties have long been on the radar of automakers. With the improvement of medical technology, metal implantation in human body is a very common surgical operation. Due to the weak rejection reaction of titanium metal with human tissue, it is widely used in artificial bones, artificial joints, artificial teeth and other human implants.

There are many classification methods for castings: according to the different metal materials used, they are divided into steel castings, iron castings, copper castings, aluminum castings, magnesium castings, zinc castings, titanium castings, etc. Each type of casting can be further divided into different types according to its chemical composition or metallographic structure. For example, iron castings can be divided into gray iron castings, nodular iron castings, vermicular iron castings, malleable iron castings, alloy iron castings, etc.; According to different mold forming methods, castings can be divided into ordinary sand castings, metal castings, die castings, centrifugal castings, continuous castings, investment castings, ceramic castings, electroslag remelting castings, bimetallic castings, etc. Among them, ordinary sand castings are the most widely used, accounting for about 80% of the total casting output. Aluminum, magnesium, zinc and other non-ferrous metal castings are mostly die castings.

Features

1. Low Density and High Specification Strength

2. Excellent Corrosion Resistance

3. Good Resistance to Effect of Heat

4. Excellent Bearing to Cryogenics Property