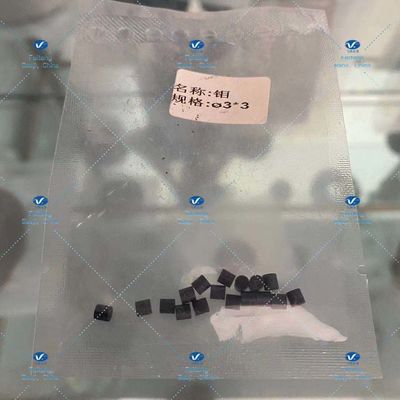

Anti Sulfur 3*3 Molybdenum Evaporation Pellets High Melting Point

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

| Model Number | Molybdenum Evaporation Pellets |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Vacuum package |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Material | Molybdenum | Packaging | Vacuum Packaging |

|---|---|---|---|

| Brand Name | Feiteng | Certification | GB/T19001-2016 Idt ISO9001:2015 GJB9001C-2017 |

| Place Of Orgin | Baoji, Shaanxi, China | Size | φ3*3 |

| Port Of Delivery | Xi'an Port, Beijing Port, Shanghai Port, Guangzhou Port, Shenzhen Port | ||

| Highlight | 3*3 Molybdenum Evaporation Pellets,Anti Sulfur Molybdenum Evaporation Pellets,Molybdenum Pellets High Melting Point |

||

Molybdenum 3*3 Evaporation Pellets Packaging Vacuum

| Port of delivery |

Xi'an port, Beijing port, Shanghai port, Guangzhou port, Shenzhen port |

| Material | Molybdenum |

| Size | φ3*3 |

| Packaging | Vacuum Packaging |

Molybdenum is a silver-white metal, hard and tough. All kinds of tissues in human body contain molybdenum, the total amount in human body is about 9 mg, and the highest content is in liver and kidney. Molybdenum is a silver-white metal with an atomic radius of 0.14 nm, atomic volume of 235.5px/mol and coordination number of 8. The crystal is an AZ-type body centered cubic crystal system with space group Oh9. So far, no isomerism transformation has been found in it. Molybdenum, which has a high melting point, is the sixth most common element in nature and is called a refractory metal. Molybdenum is mainly used in the iron and steel industry, most of which are directly used in steelmaking or cast iron after pressing industrial molybdenum oxide, and a small part is melted into ferric molybdenum and then used in steelmaking. The content of molybdenum in low alloy steel is not more than 1%, but the consumption of this aspect accounts for about 50% of the total consumption of molybdenum. The addition of molybdenum to stainless steel can improve the corrosion resistance of steel. Adding molybdenum to cast iron can improve its strength and wear resistance. Nickel-based super alloy containing 18% molybdenum has the characteristics of high melting point, low density and small thermal expansion coefficient, etc., which is used in the manufacture of various high temperature resistant parts in aviation and aerospace. Molybdenum metal is widely used in electronic devices such as electron tubes, transistors and rectifiers. Molybdenum oxide and molybdate are excellent catalysts in the chemical and petroleum industries. Molybdenum disulfide is an important lubricant used in the aerospace and mechanical industries. In addition, due to its unique anti-sulfur properties, molybdenum disulfide can catalyze the hydrogenation of carbon monoxide to alcohols under certain conditions, and is a very promising CHEMICAL catalyst for C1. Molybdenum is one of the essential trace elements in plants and is used as trace element fertilizer in agriculture.

Advantage:

1: Low friction coefficient, high yield strength;

2: good anti-sulfur property;

3: good electrical conductivity;

4: high temperature resistance;