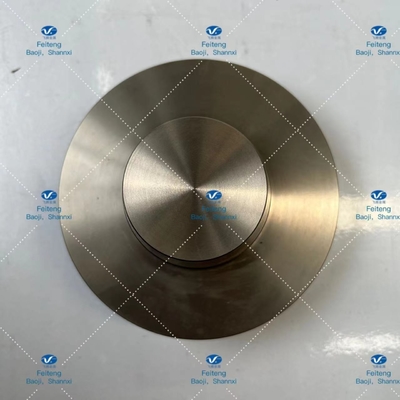

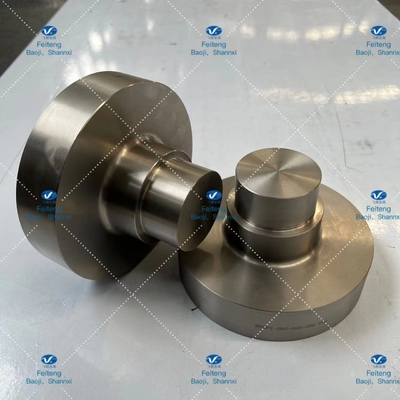

Gr2 ASTM B348 Titanium Valve Cover Titanium Forging Parts Heat Resistance

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

| Model Number | Shaft Sleeve |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Service | Customized OEM | Size | Customized Size,Technical Drawing,as Customer's Drawings |

|---|---|---|---|

| Material | Titanium | Application | Industrial Equipment,Auto Part,Car Spare Parts,Camera Components Equipment |

| Item Name | Titanium Valve Cover | Packaging | Wooden Case |

| Grade | Gr2 | Port Of Delivery | Xi'an Port, Beijing Port, Shanghai Port, Guangzhou Port, Shenzhen Port |

| Highlight | ASTM B348 Titanium Valve Cover,Gr2 Titanium Valve Cover,Shaft Sleeve Titanium Valve Cover |

||

Shaft Sleeve Gr2 ASTM B348 CustomTtitanium Parts Titanium Customized Titanium Forgings

| Origin |

Baoji, Shaanxi, China |

| Customized | Customized |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

|

Port of delivery |

Xi'an port, Beijing port, Shanghai port, Guangzhou port, Shenzhen port |

|

Grade |

Gr2 |

Titanium is a widely used metal, due to its light weight, higher strength than aluminium alloy, can maintain a higher strength than aluminium at high temperature and is highly valued by the aviation industry. Titanium has a wide range of uses in the military industry.

The titanium bonnet is a valve part with stem seals, used to connect or support the actuator, the bonnet and the valve body can be integral, or can be separated. The valve cover in the gate valve mainly acts as a compression packing.

A bonnet is a valve part with a stem seal that connects or supports an actuator,

Cover and body may be integral or separate gate valves in which the cover is primarily pressed

Packing action. The purpose of the valve cover has two: one is to position the valve stem to ensure the normal transmission of the valve stem

The switch. The second is the sealing effect, with a certain strength, to prevent the flow of internal fluid. The cover

The main machining parts of the parts are holes. Outer circle surface processing according to the accuracy of the requirements can choose turning

And grinding. The selection of hole machining method is more complex, need to consider the structural point, aperture

Size, aspect ratio, precision and roughness requirements, production scale and other factors. The essence of

Holes with higher degree requirements are often processed in sequence by several methods.

Benefits:

1. Low density and high strength

2. Customized according to the drawings required by customers

3. Strong corrosion resistance

4. Strong heat resistance

5. Low temperature resistance

6. Heat resistance