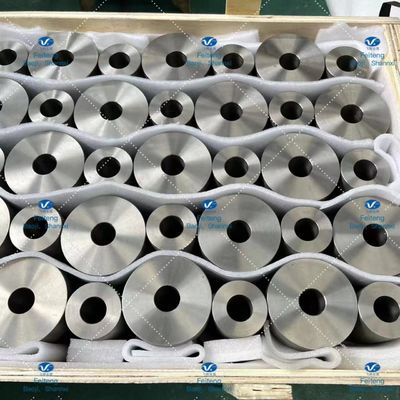

High Strength Custom Titanium Parts Gr2 Titanium Shaft Sleeve

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

| Model Number | Titanium Shaft Sleeve |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Service | Customized OEM | Size | Customized Size,Technical Drawing,as Customer's Drawings |

|---|---|---|---|

| Material | Titanium | Application | Industrial Equipment,Auto Part,Car Spare Parts,Camera Components Equipment |

| Item Name | Shaft Sleeve | Packaging | Wooden Case |

| Grade | Gr2 | Certification | GB/T19001-2016 Idt ISO9001:2015 GJB9001C-2017 |

| Highlight | High Strength Shaft Sleeve,Titanium Shaft Repair Sleeve,Gr2 Shaft Protection Sleeve |

||

Shaft Sleeve Gr2 CustomTtitanium Parts Titanium

| Origin |

Baoji, Shaanxi, China |

| Customized | Customized |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

|

Port of delivery |

Xi'an port, Beijing port, Shanghai port, Guangzhou port, Shenzhen port |

|

Grade |

Gr2 |

Titanium is a widely used metal, due to its light weight, higher strength than aluminum alloy, can maintain a higher strength than aluminum at high temperature and is highly valued by the aviation industry. Titanium has a wide range of uses in the military industry. Nuclear powered submarines, hydrofoil boats, anti-tank missiles, missile launchers, bulletproof vests, etc. In the aviation industry, civilian aircraft, strategic rocket engines, spacecraft satellite antennas and other large amounts of titanium.

Shaft sleeve is a cylindrical mechanical part on a rotating shaft, and is a component of a sliding bearing. In general, the bushing and the bearing block use interference fit, and the shaft use clearance fit.

The bushing refers to the sleeve on the propeller shaft or stern shaft. And bearing is in the process of mechanical transmission to fix and reduce the load friction coefficient of components.

The bushing and bearing have in common that they both bear the load of the shaft.

The difference between the two is that the shaft sleeve is a whole structure, rotation is the relative motion between the shaft and the shaft sleeve; The bearing is a split type, and the inner and outer rings of the bearing move relative to each other when rotating. But in essence, the sleeve is actually a kind of sliding bearing.

1. Low density and high strength

2. Customized according to the drawings required by customers

3. Strong corrosion resistance

4. Strong heat resistance

5. Low temperature resistance

6. Heat resistance