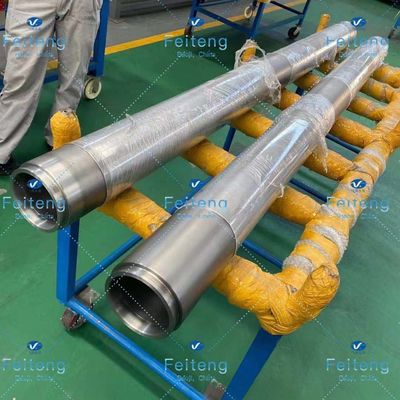

Seamless Niobium Vacuum Coating Tube Targets 155OD*125ID*2000mm

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015; GJB9001C-2017 |

| Model Number | Niobium Tube Target |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Vacuum package in wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Size | φ155*φ125*2000 | Model Number | Niobium Tube Target |

|---|---|---|---|

| Packaging | Vacuum Package In Wooden Case | Certification | GB/T19001-2016 Idt ISO9001:2015; GJB9001C-2017 |

| Brand Name | Feiteng | Place Of Origin | Baoji, Shaanxi, China |

| Highlight | Niobium Tube Targets 155OD,Vacuum Coating Tube Targets 125ID,Seamless Niobium tube Target 2000mm |

||

Niobium Tube Target Vacuum Coating Target 155OD*125ID*2000 Seamless Tube

| Item name |

Niobium Tube Targets |

| Size | φ155*Iφ125*2000 |

| Packaging | Vacuum package in wooden case |

| Port of place | Xi'an port, Beijing port, Shanghai port, Guangzhou port, Shenzhen port |

Niobium is less electropositive than zirconium, to its left. The size of its atoms is almost identical to that of the tantalum below it, which is caused by lanthanide shrinkage. This makes niobium chemically very similar to tantalum. Although it is not as resistant to corrosion as tantalum, it is cheaper and more common, so tantalum is often used as an alternative in less demanding situations, such as coating chemical tanks in chemical plants.

The metal niobium can be prepared by electrolytic melting of potassium sevoflonobate, can also be made by reducing potassium sevoflonobate with sodium metal or reducing niobium pentaoxide with aluminum metal. Pure niobium is used to remove residual gas in the electron tube, and niobium doping in steel can improve the oxidation resistance of steel at high temperature and improve the welding performance of steel. Niobium is also used to make high temperature cermets. The addition of niobium as a microalloyed element does not change the structure of iron, but changes the microstructure of steel by combining with carbon nitrogen sulfur in steel. The strengthening effect of niobium on steel is mainly fine grain strengthening and dispersion strengthening, niobium can form stable carbides and carbonitrides with carbon and nitrogen in steel. Moreover, carbides can be dispersed to form steels with fine crystallization.

The coating target is a sputtering source that forms various functional films on the substrate by magnetron sputtering, multi-arc ion plating or other types of coating systems under appropriate technological conditions. To put it simply, the target material is the target material of high-speed charged particles bombardment. When used in high-energy laser weapons, different power densities, different output waveforms and different wavelengths of laser interact with different targets, different killing and destruction effects will be produced. For example, evaporative magnetron sputtering coating is heated evaporation coating, aluminum film, etc. Change different target material (such as aluminum, copper, stainless steel, titanium, nickel target, etc.), can get different film system (such as super hard, wear resistant, corrosion resistant alloy film, etc.).

Features:

Small volume

Light weight

High temperature oxidation resistance

The corrosion resistance