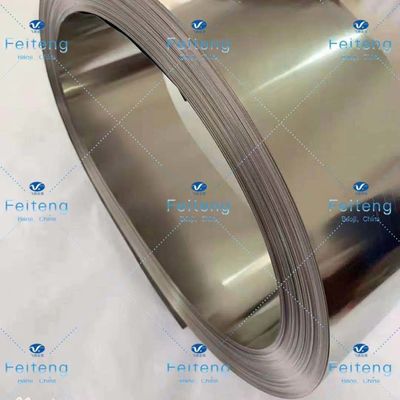

High Strength Gr2 ASTM B265 Titanium Foil Roll

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

| Model Number | Titanium Foil Roll |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Brand Name | Feiteng | Model Number | Titanium Foil Roll |

|---|---|---|---|

| Certification | GB/T19001-2016 Idt ISO9001:2015 MANAGEMENT SYSTEM CNAS C034-M | Packaging | Wooden Case |

| Grade | Gr2 | Place Of Origin | Baoji, Shaanxi, China |

| Material | Titanium | Specification | ASTM B265 |

| Highlight | ASTM B265 Titanium Foil Roll,Gr2 Titanium Foil Roll,High Strength Ti Foil Roll |

||

Titanium Foil Roll Gr2 ASTM B265 Foil Roll

| Product | Titanium Foil Roll |

| Grade | Gr2 |

| Packaging | Wooden case |

| Port of delivery | Xi'an port, Beijing port, Shanghai port, Guangzhou port, Shenzhen port |

Titanium is a widely used metal, due to its light weight, higher strength than aluminium alloy, can maintain a higher strength than aluminium at high temperature and is highly valued by the aviation industry. The good mechanical properties of titanium as a structural material are achieved by strictly controlling the appropriate impurity content and adding alloying elements. The smelting process of titanium is generally carried out at a high temperature above 800℃, so it must be operated in a vacuum or under the protection of an inert atmosphere. Titanium's lightweight, high-strength properties have long been on the radar of automakers. With the improvement of medical technology, metal implantation in human body is a very common surgical operation. Due to the weak rejection reaction of titanium metal with human tissue, it is widely used in artificial bones, artificial joints, artificial teeth and other human implants.

In modern times, the methods of making metal foil include forging, vacuum evaporation, powder rolling, electrolysis and calendaring, etc., but calendaring and electrolysis are still the main methods in large-scale production. Calendaring method to produce aluminium, foil as a representative, because of its use is very wide, so the development is extremely rapid, has formed an independent processing industry. Although both methods can be used in the production of copper, nickel and iron foil, electrolysis has obviously taken advantage. In calendaring, the foil is formed from thick to thin, while in electrolysis the foil is formed in reverse. Processing costs always increase with the increase of the process. Therefore, in addition to meeting performance requirements, thickness is also a factor to be considered when selecting a production method. Early copper foil production had been 0.8 mm as a boundary, thinner than its suitable electrolysis method. With the improvement of processing equipment and the boundary has been reduced to 0.2~0.4 mm. Calendar copper foil can be as thin as 6 microns, but the width is limited. In the future, the demand for thin and wide foil tends to be more and more. For example, copper foil half a meter wide and 50 microns thick has gradually been replaced by one meter wide and 35 microns thick. The widest one requires a width of up to two meters, so the calendaring production is limited. The use of copper foil, electrolytic copper foil, has accounted for 90-95%. Others such as nickel, iron and alloy foil have similar trends.

Six big features:

1. High strength

2. The corrosion

3. High temperature resistance

4. Good low temperature resistance

5. Environmentally friendly metals

6. Good thermal conductivity