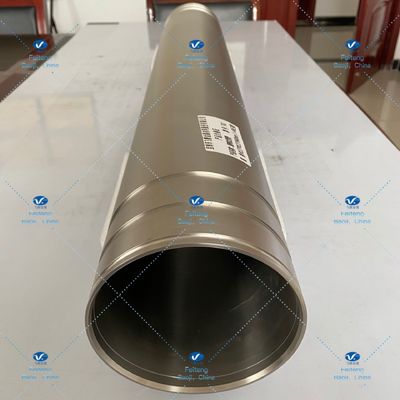

Vacuum Coating Gr1 Titanium Sputtering Target 133OD*125ID*840L

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015; GJB9001C-2017 |

| Model Number | Titanium tube target |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Vacuum package in wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Model Number | Titanium Tube Target | Size | φ133*φ125*840 |

|---|---|---|---|

| Certification | GB/T19001-2016 Idt ISO9001:2015; GJB9001C-2017 | Packaging | Vacuum Package In Wooden Case |

| Grade | Gr1 | Specification | ASTM B861-06 A |

| Place Of Origin | Baoji, Shaanxi, China | Brand Name | Feiteng |

| Highlight | Gr1 Titanium Sputtering Target,Titanium Sputtering Target 133OD,125mm Vacuum Coating Target |

||

Titanium Tube Target Titanium Gr1 ASTM B861-06 a 133OD*125ID*840L Sputtering Vacuum Coating Target

| Item name |

Titanium tube target |

| Size | φ133*φ125*840 |

| Grade | Gr1 |

| Packaging | Vacuum package in wooden case |

| Port of place | Xi'an port, Beijing port, Shanghai port, Guangzhou port, Shenzhen port |

The coating target is a sputtering source that forms various functional films on the substrate by magnetron sputtering, multi-arc ion plating or other types of coating systems under appropriate technological conditions. To put it simply, the target material is the target material of high-speed charged particles bombardment. When used in high-energy laser weapons, different power densities, different output waveforms and different wavelengths of laser interact with different targets, different killing and destruction effects will be produced. For example, evaporative magnetron sputtering coating is heated evaporation coating, aluminium film, etc. Change different target materials (such as aluminium, copper, stainless steel, titanium, nickel target, etc.), can get different film systems (such as super hard, wear-resistant, anti-corrosion alloy film, etc.)

An orthogonal magnetic field and electric field are added between the sputtered target pole (cathode) and anode, and the required inert gas (usually Ar gas) is filled in a high vacuum chamber. The permanent magnet forms a magnetic field of 250 ~ 350 Gauss on the surface of the target material, which forms an orthogonal electromagnetic field with the high voltage electric field. Under the action of electric field, Ar gas ionization into positive ions and electrons, target and has certain negative pressure, from the action of the target from the extremely affected by magnetic field and increase of working gas ionization probability, form a high density plasma near the cathode, Ar ion under the action of lorentz force, speed up to fly to the target surface, bombarding target surface at a high speed, The sputtered atoms on the target follow the momentum conversion principle and fly away from the target with high kinetic energy to the substrate for film deposition. Magnetron sputtering is generally divided into two kinds: DC sputtering and rf sputtering. The principle of DC sputtering equipment is simple, and the rate is fast when sputtering metal. Rf sputtering is more widely used, in addition to sputtering conductive materials, also can sputter non-conductive materials, but also reactive sputtering to prepare oxides, nitrogen and carbide and other compound materials. If the frequency of radio frequency is increased, it becomes microwave plasma sputtering. Now, the electron cyclotron resonance (ECR) type microwave plasma sputtering is commonly used.

Features

1. Low density and high strength

2. Customized according to the drawings required by customers

3. Strong corrosion resistance

4. Strong heat resistance

5. Low temperature resistance

6. Heat resistance