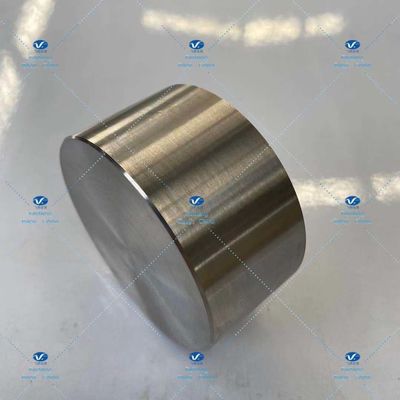

Feiteng Grade 5 OD75*37 Round Titanium Alloy Discs

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

| Model Number | Titanium Discs |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Advantage | Light Quality,High Strengthen Anticorrossive,Corrosion Resistance,acid And Base Resistance | Name | Titanium Discs |

|---|---|---|---|

| Size | φ75*37 | Grade | Gr5 |

| Application | Industrial,Medical,exhaust Hanger,chemical,Condenser | Shape | Round |

| Package | Wooden Case | Specification | ASTM B381 |

| Highlight | OD75*37 Round Titanium Alloy Discs,Feiteng Grade 5 Titanium Alloy Discs,OD75 Titanium Alloy Disk |

||

Titanium Discs Gr5 ASTM B381 OD75*37 Titanium Alloy Discs Titanium Forging Titanium products

|

Name |

Titanium Bars |

|

Grade |

Gr5 |

|

Transport Package |

Wooden case |

|

Origin |

Baoji, Shaanxi, China |

|

Port of delivery |

Xi'an port, Beijing port, Shanghai port, Guangzhou port, Shenzhen port |

| Shape | Round |

Titanium is a widely used metal, due to its light weight, higher strength than aluminum alloy, can maintain a higher strength than aluminum at high temperature and is highly valued by the aviation industry. Titanium has a wide range of uses in the military industry. Nuclear powered submarines, hydrofoil boats, anti-tank missiles, missile launchers, bulletproof vests, etc. In the aviation industry, civilian aircraft, strategic rocket engines, spacecraft satellite antennas and other large amounts of titanium. In seawater, titanium has incomparable corrosion resistance, especially the high speed erosion corrosion of seawater. At present, many countries have developed a variety of advanced titanium submersible, submarine, submarine laboratory equipment to carry out Marine research. In addition, titanium equipment and devices are widely used in coastal power stations, offshore oil production equipment, seawater desalination, Marine chemical production and mariculture. Titanium's lightweight, high-strength properties have long been on the radar of automakers. With the improvement of medical technology, metal implantation in human body is a very common surgical operation. Due to the weak rejection reaction of titanium metal with human tissue, it is widely used in artificial bones, artificial joints, artificial teeth and other human implants.

Titanium discs have good thermal strength, good weldability and excellent corrosion resistance. Its disadvantage is low strength at room temperature. It is usually used as heat-resistant and corrosion resistant material. Titanium alloy is widely used in various fields because of its high specific strength, good corrosion resistance and good heat resistance. The industrial production of titanium began in 1948, and the demand of the aviation industry made the titanium industry develop at an average annual rate of about 8%. At present, the annual output of international titanium alloy processing materials has reached 4 million tons, and there are nearly 30 kinds of titanium alloy trademarks. Titanium alloy is mainly used to manufacture aircraft engine compressor parts, followed by layout parts of rockets, missiles and high-speed aircraft. In the mid-1960s, titanium and its alloys have been used in general industries, such as electrodes for electrolytic industry, condensers for power stations, oil refining and desalination heaters and environmental pollution control equipment. Titanium and its alloys have become an anticorrosion material.

Product advantages

1. Convenient handling.

2. Strong corrosion resistance

3. low fluid resistance

4. High mechanical strength