ISO9001 ASTM Titanium Rotary Target Corrosion Resistance

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

| Model Number | Titanium tube target |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

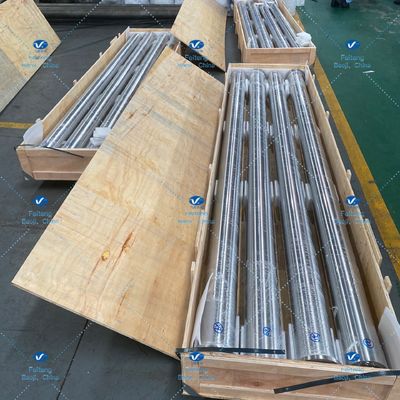

| Packaging Details | Vacuum package in wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

| Grade | Titanium Gr2 | Application | Semiconductor,electronic,displayer,etc |

|---|---|---|---|

| Packaging | Vacuum Package In Wooden Case | Color | Shine With Grey Or Dark Grey Metallic Luster |

| Standard | ASTM B861-06 A | Place Of Origin | Baoji, Shaanxi, China |

| Shape | Tube | Certification | GB/T19001-2016 Idt ISO9001:2015 GJB9001C-2017 |

| Highlight | ISO9001 ASTM Titanium Rotary Target,Titanium Rotary Target Corrosion Resistance,ASTM B861 ito rotary target |

||

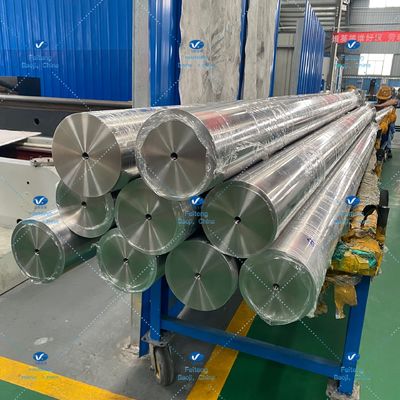

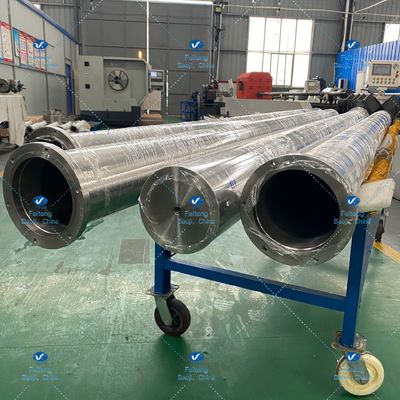

Titanium Tube Target Titanium Gr2 133OD*125ID*2940L Include Flange ASTM B861-06 a Titanium Rotary Target

| Name | Titanium tube target |

| Standard |

ASTM B861-06 a |

|

Transport Package |

Vacuum package in wooden case |

|

Origin |

Baoji, Shaanxi, China |

|

Port of deliver |

Xi'an port, Beijing port, Shanghai port, Guangzhou port, Shenzhen port |

| Size | φ133*φ125*2940(include flange) |

The development trend of tube target technology is closely related to the development trend of thin film technology in downstream industries. With the technological improvement of applied industries in film products or components, target technology should also change. In addition, in recent years, flat panel display (FPD) has greatly replaced the computer display and TV market dominated by cathode ray tube (CRT), which will also greatly increase the technology and market demand of ITO target. In addition, in terms of storage technology. Demand for high-density, high-capacity hard drives and high density rewritable optical discs continues to increase, leading to changes in the demand for target products in the application industry. Next, we will introduce the main application fields of targets and the development trend of targets in these fields.

Vacuum coating is a method of heating metal or non-metallic materials under high vacuum to evaporate and condense on the surface of plated parts (metal, semiconductor, or insulator).

Vacuum coating is an important aspect in the field of vacuum application. It is a new process of film preparation based on vacuum technology, using physical or chemical methods, and absorbing a series of new technologies such as electron beam, molecular beam, ion beam, plasma beam, RF and magnetron, to provide scientific research and practical production. Simply speaking, the method of depositing or depositing metal, alloy or compound in vacuum is made on the coated object (substrate, substrate, or substrate), which is called vacuum coating.

Main advantages

- Low Density and High Specification Strength

- Customer request customization

- Excellent Corrosion Resistance

- Good Resistance to Effect of Heat

- Excellent Bearing to Cryogenics Property

- Good Thermal Properties

- Low Modulus of Elasticity