ASTM B861 Titanium Gr2 Tube Sputtering Target 2940mm Length

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

| Model Number | Titanium tube target |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

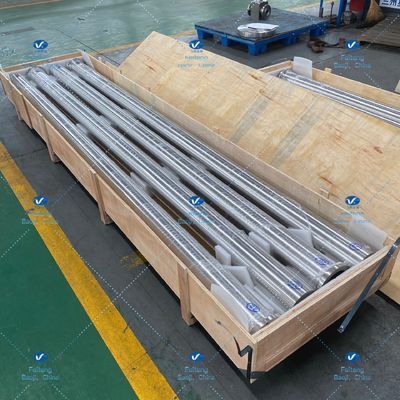

| Packaging Details | Vacuum package in wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Application | Semiconductor,electronic,displayer,etc | Shape | Tube |

|---|---|---|---|

| Color | Shine With Grey Or Dark Grey Metallic Luster | Standard | ASTM B861-06 A |

| Certification | GB/T19001-2016 Idt ISO9001:2015 GJB9001C-2017 | Packaging | Vacuum Package In Wooden Case |

| Grade | Titanium Gr2 | Place Of Origin | Baoji, Shaanxi, China |

| Highlight | Titanium Gr2 Tube Sputtering Target,ASTM B861 Tube Sputtering Target,2940L titanium sputtering target |

||

Titanium Tube Target ASTM B861-06 a 133OD*125ID*2940L Include Flange Titanium Gr2

| Name | Titanium tube target |

| Standard | ASTM B861 |

|

Transport Package |

Vacuum package in wooden case |

|

Origin |

Baoji, Shaanxi, China |

|

Port of deliver |

Xi'an port, Beijing port, Shanghai port, Guangzhou port, Shenzhen port |

| Size | φ133*φ125*2940(include flange ) |

Tube target is a sputtering source which can form various functional films on the substrate by magnetron sputtering multi-arc ion plating or other types of coating system under appropriate technological conditions. In short, the target is the target material bombarding by high-speed charged particles. When used in high-energy laser weapons, different power densities, output waveforms and wavelengths of lasers interact with different targets, different killing and destruction effects will be produced. For example, evaporation magnetron sputtering coating is heating evaporation coating, aluminum film, etc. Replacement of different target materials (such as aluminum, copper, stainless steel, titanium, nickel target, etc.), can get a different film system (e.g., hard, wear-resisting, anti-corrosion alloy membrane, etc.) vacuum coating is refers to under the condition of high vacuum heating metal or nonmetal material, make its evaporation and condensation in the plating parts, metal, semiconductor or insulator surface to form a thin film of a method.

Vacuum coating is an important aspect of vacuum application field, it is based on vacuum technology, using physical or chemical methods, and the absorption of electron beam, molecular beam, ion beam, ion beam, radio frequency and magnetic control and a series of new technologies, for scientific research and practical production to provide a new film preparation process.

Main advantages

- Low Density and High Specification Strength

- Customer request customization

- Excellent Corrosion Resistance

- Good Resistance to Effect of Heat

- Excellent Bearing to Cryogenics Property

- Good Thermal Properties

- Low Modulus of Elasticity