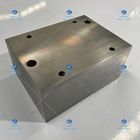

GB/T19001-2016 Custom Titanium Parts With Metallic Luster

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015; GJB9001C-2017 |

| Model Number | Titanium parts |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

| Place Of Origin | Baoji, Shaanxi, China | Brand Name | Feiteng |

|---|---|---|---|

| Model Number | Titanium Parts | Grade | Gr5 |

| Certification | GB/T19001-2016 Idt ISO9001:2015; GJB9001C-2017 | Specification | ASTM B381 |

| Highlight | GBT19001 2016 Custom Titanium Parts,Metallic Luster Custom Titanium Parts,ASTM B381 Titanium Parts |

||

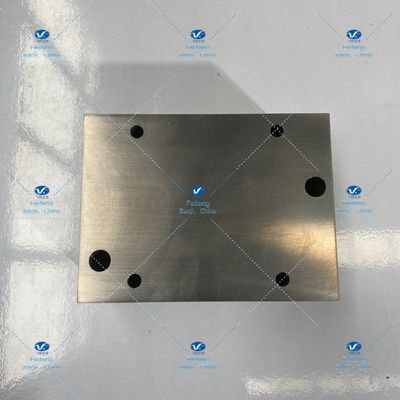

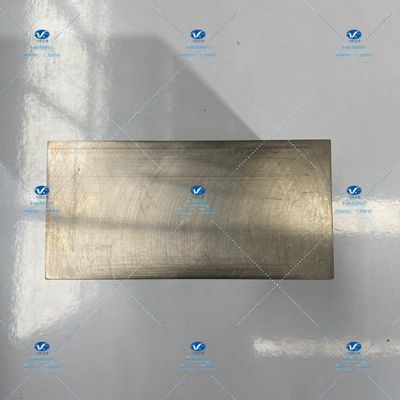

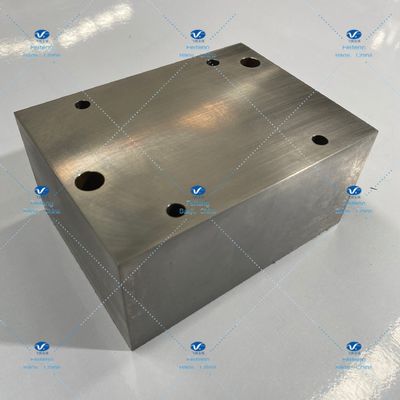

Titanium parts Gr5 ASTM B381 Custom Titanium Parts

| Company | Feiteng |

| Item name | Titanium parts |

| Grade | Gr5 |

| Standard | ASTM B381 |

| Packaging | Wooden case |

| Port of delivery | Xi'an port, Beijing port, Shanghai port, Guangzhou port, Shenzhen port |

Titanium has a metallic luster and ductility. Titanium is characterized by its low density, high mechanical strength and ease of processing. The plasticity of titanium depends largely on its purity. The purer the titanium, the more plastic it is. Good corrosion resistance, not affected by the atmosphere and seawater. At room temperature, it will not be corroded by hydrochloric acid below 7%, sulfuric acid below 5%, nitric acid, aqua regia or dilute alkali solution; Only hydrofluoric acid, concentrated hydrochloric acid, concentrated sulfuric acid can act on it. The presence of impurities in titanium greatly affects its mechanical properties, especially the interstitial impurities (oxygen, nitrogen, carbon) can greatly improve the strength of titanium and significantly reduce its plasticity. The good mechanical properties of titanium as a structural material are achieved by strictly controlling the appropriate impurity content and adding alloying elements.

Titanium is a widely used metal, due to its light weight, higher strength than aluminum alloy, can maintain a higher strength than aluminum at high temperature and is highly valued by the aviation industry. Titanium has a wide range of uses in the military industry. Nuclear-powered submarines, hydrofoil boats, anti-tank missiles, missile launchers, bulletproof vests, etc. In the aviation industry, civilian aircraft, strategic rocket engines, spacecraft satellite antennas and other large amounts of titanium. In seawater, titanium has incomparable corrosion resistance, especially the high speed erosion corrosion of seawater. At present, many countries have developed a variety of advanced titanium submersible, submarine, submarine laboratory equipment to carry out Marine research. In addition, titanium equipment and devices are widely used in coastal power stations, offshore oil production equipment, seawater desalination, Marine chemical production and mariculture. Titanium's lightweight, high-strength properties have long been on the radar of automakers. With the improvement of medical technology, metal implantation in human body is a very common surgical operation. Due to the weak rejection reaction of titanium metal with human tissue, it is widely used in artificial bones, artificial joints, artificial teeth and other human implants.