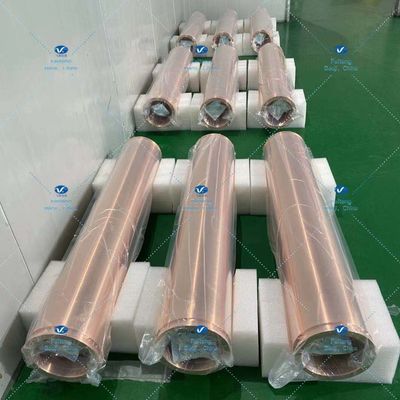

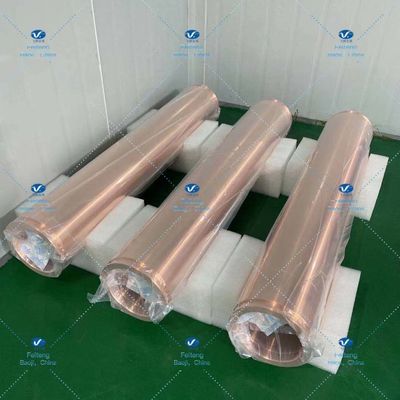

High Conductivity 99.97 Percent Copper Target 155OD*125ID*888 Copper Tube Vacuum Package

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

| Model Number | Copper Tube Target |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Vacuum package in wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

| Packaging | Vaccum Package | Certification | GB/T19001-2016 Idt ISO9001:2015 MANAGEMENT SYSTEM CNAS C034-M |

|---|---|---|---|

| Model Number | Copper Tube Target | Size | φ155*φ125*888 |

| Material | Oxygen-Free Copper | Place Of Origin | Baoji, Shaanxi, China |

| Pure | 99.97% | Brand Name | Feiteng |

| Highlight | 99.97 Percent Copper Target,155mm High Conductivity Copper Target,99.97% Good Weldability tube Target |

||

Copper Tube Target 155OD*125ID*888 Oxygen-Free Copper Pure 99.97%

| Product | Copper Tube Target |

| Size | φ155*φ125*888 |

| Grade | Oxygen-free copper |

| Packaging | Vacuum package in wooden case |

| Port of delivery | Xi'an port, Beijing port, Shanghai port, Guangzhou port, Shenzhen port |

The coating target is a sputtering source that forms various functional films on the substrate by magnetron sputtering, multi-arc ion plating or other types of coating systems under appropriate technological conditions. To put it simply, the target material is the target material of high-speed charged particles' bombardment. When used in high-energy laser weapons, different power densities, different output waveforms and different wavelengths of laser interact with different targets, different killing and destruction effects will be produced. For example, evaporative magnetron sputtering coating is heated evaporation coating, aluminium film, etc. Change different target materials (such as aluminium, copper, stainless steel, titanium, nickel target, etc.), can get different film systems (such as super hard, wear-resistant, anti-corrosion alloy film, etc.)

Vacuum coating refers to heating metal or non-metal materials under high vacuum conditions, so that it evaporates and condenses on the surface of plated parts (metal, semiconductor or insulator) and forms a film method.

Vacuum coating is an important aspect in the field of vacuum application. It is based on vacuum technology, using physical or chemical methods, and absorbing a series of new technologies such as electron beam, molecular beam, ion beam, plasma beam, radio frequency and magnetic control, providing a new process for the preparation of thin films for scientific research and practical production. To put it simply, the metal, alloy or compound in vacuum evaporation or sputtering, so that it is coated in the object (called substrate, substrate or matrix) on the solidification and deposition method, called vacuum coating.

PVD vacuum coating is a surface treatment process in which titanium, graphite, gold, crystal and other metals or non-metal, gas and other materials are formed on the substrate by sputtering, evaporation or ion plating technology. Compared with the traditional chemical coating method, PVD has many advantages: such as no pollution to the environment, is green environmental protection process; No harm to the operator; The film layer is firm, good compactness, strong corrosion resistance and uniform thickness.

IP Rose Gold is an alloy of gold and copper, which is widely used in jewellery design and processing due to its very fashionable and beautiful rose-red colour. Also known as pink gold, red gold.

Advantages:

1, high conductivity

2. Good thermal conductivity

3, good weldability

4, excellent plasticity and ductility

5, excellent cold working performance