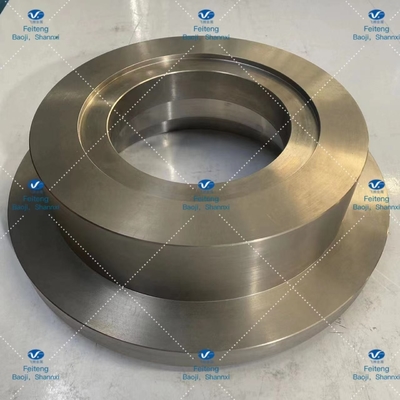

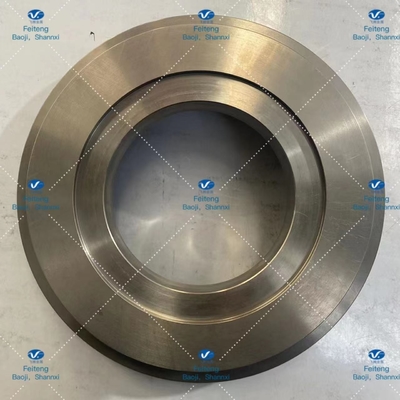

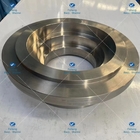

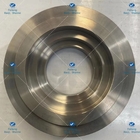

Sophisticated Mechanical Titanium Rings Gr2 Anti Corrosion

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

| Model Number | Titanium Ring |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Brand Name | Feiteng | Model Numble | Titanium Before The Gland |

|---|---|---|---|

| Grade | Gr2 | Specification | ASTM B348 |

| Packaging | Woofen Case | Place Of Origin | Baoji, Shaanxi, China |

| Certification | GB/T19001-2016 Idt ISO9001:2015 GJB9001C-2017 | ||

| Highlight | Sophisticated Titanium Rings,Titanium Rings Gr2,Anti Corrosion Titanium Rings |

||

Titanium Before The Gland Gr2 ASTM B348 Titanium Processing Titanium Forged

|

Item Name |

Titanium Rings |

|

Grade |

Gr2 |

|

Standard |

ASTM B348 |

|

Test |

Ultrasonic testing |

|

Packaging |

Wooden case |

|

Port of delivery |

Xi'an port, Beijing port, Shanghai port, Guangzhou port, Shenzhen port |

At room temperature, the chemical activity of titanium is very small and can react with a few substances such as hydrofluoric acid, but when the temperature increases, the activity of titanium increases rapidly, especially at high temperature, titanium can react violently with many substances.

Only hydrofluoric acid, concentrated hydrochloric acid, concentrated sulfuric acid can act on it. The presence of impurities in titanium greatly affects its mechanical properties, especially the interstitial impurities (oxygen, nitrogen, carbon) can greatly improve the strength of titanium and significantly reduce its plasticity. The good mechanical properties of titanium as a structural material are achieved by strictly controlling the appropriate impurity content and adding alloying elements.

The good mechanical properties of titanium ring as a structural material are achieved by strictly controlling the appropriate impurity content and adding alloying elements. Titanium ring is an ideal material for aircraft and engine because of its high specific strength, good mechanical properties and good corrosion resistance. With the development of machining technology, titanium alloy has been widely used in the manufacture of compressor section, engine hood, exhaust device and other structural frame parts of aircraft engine in recent years. Titanium processing industry is developing fast at present, it not only with many of the good qualities of titanium industry made a lot of love, and also have sophisticated metal plastic working skills to be able to use, which has a long history of steel and non-ferrous metals processing skills and equipment to be able to use and learn about, this makes the plasticity of titanium processing skills, able to quickly improve and sophisticated.

Before The Gland Main advantages and applications:

1. Low density.

2. Higher than strength.

3. Small elastic modulus, high fatigue strength, suitable for spring;

4. Low coefficient of thermal expansion.

5. Good corrosion resistance.

6. Good formability.