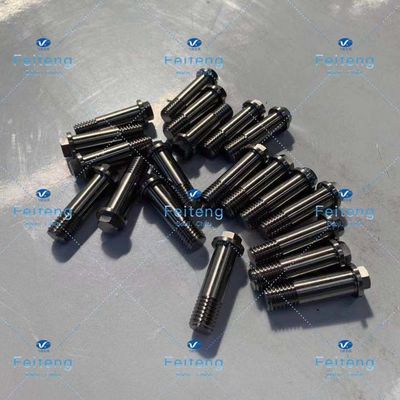

OEM Gr5 ASTM B381-06 A Titanium Fasteners Pin Shaft

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

| Model Number | Custom Titanium Parts |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Origin | Baoji, Shaanxi, China | Surface Treatment | Electric Heating |

|---|---|---|---|

| Application | Industrial Equipment | Service | Drawings To Customize |

| Material | Titanium | Item Name | Custom Titanium Parts |

| Certification | GB/T19001-2016 Idt ISO9001:2015 GJB9001C-2017 | Port Of Delivery | Xi'an Port, Beijing Port, Shanghai Port, Guangzhou Port, Shenzhen Port |

| Highlight | Gr5 Titanium Fasteners,ASTM B381-06 A Titanium Fasteners,OEM Titanium Alloy Pin Shaft |

||

Titanium Alloy Pin Shaft Gr5 ASTM B381-06 a Titanium Parts Titanium Precision Parts

| Item name | Custom Titanium Parts |

| Material | Titanium |

| Standard | ASTM B381-06 a |

| Surface | Electric heating |

| Transport Package | wooden case |

| Origin |

Baoji, Shaanxi, China |

Titanium Alloy Pin Shaft is a part used in construction machinery. It is a small cylindrical or conical metal rod with a sharp end like a nail, threaded part, a grooved or concave head, used alone.

Inspection of screws should start from the wire of screws. The quality of precision screw is directly related to the wire that produces the screw. Good screw wire opens the screw more beautiful. What screw head burst ah, what tooth thread is bad. Good screw wire won't discover this kind of circumstance commonly.

The detection of screw head forming, in screw forming, first of the production of screw mold detection. A good mold can produce a good screw product. In is the production of screw machine testing, which is conducive to safe and smooth production. Shape out of the screw appearance inspection to see if there is a burr, and is to shape the size of the length of the screw detection. Check whether these sizes and lengths meet the national standards or the specific requirements of customers.

The second is the detection of screw rubbing teeth. Screw rubbing tooth head when of course is dental plate. Good dental plate rub out of the teeth should be able to pass the stop gauge. All rules, all rules, all rules. There is also the detection of tooth thread pitch. Also to meet the screw national standards or customer requirements.

Finally, color detection and salt spray test were carried out on the screws returned by electroplating. See if the color of the screws returned by electroplating is good. How smooth is the surface of the screw? The salt spray test measures how long a screw will rust or how many hours of salt spray a screw will rust. After that is the shipment of screws detection. The method is to pick out the unqualified screws. Deliver the best quality screws to customers. Ensure screw quality.

Features

1. Low density and high specification strength

2. Excellent corrosion resistance

3. Good heat resistance

4. Excellent low temperature resistance

5. Non-magnetic and non-toxic

6. Good thermal performance

7. Low elastic modulus

8. Good toughness and light weight

9. High acid-base resistance

10. Resistance to high temperature, low temperature, etc