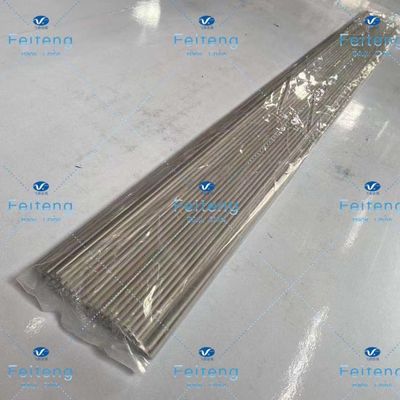

Grade 5 ASTM B863 3*1000 5KG Titanium Welding Wire

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

| Model Number | Titanium Wire |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Orgin | Baoji, Shaanxi, China | Certifaction | GB/T19001-2016 Idt ISO9001:2015 GJB9001C-2017 |

|---|---|---|---|

| Packaging | Wooden Case | Weight | 5KG |

| Size | φ3*1000 | Item Name | Titanium Wire |

| Customized | Customized | ||

| Highlight | 5KG Titanium Welding Rod,ASTM B863 Titanium Welding Rod,Grade 5 3*1000 titanium cable |

||

Titanium Wire Gr5 ASTM B863 φ3*1000 5KG Titanium Alloy Wire Titanium Welding Wire

| Name |

Titanium Wire |

| Connection | Wire |

| Port of delivery |

Xi'an port, Beijing port, Shanghai port, Guangzhou port, Shenzhen port |

| Weight | 5KG |

Titanium wire is divided into: titanium wire, titanium alloy wire, pure titanium eyewear wire, titanium straight wire, pure titanium wire, titanium wire, titanium wire, titanium hanging wire, titanium disc wire, titanium bright wire, medical titanium wire, titanium nickel alloy wire.

The titanium wire forms a stable carbide of higher hardness with carbon. The growth of the carbonized layer between titanium and carbon is determined by the diffusion rate of titanium in the carbonized layer. Only under very thin layer thickness conditions, in vacuum or in an argon-methane atmosphere, it is possible to form a sufficient adhesive strength of the carbonized powder compared with gas carburizing agent, it is possible to form a particularly hard and cohesive titanium carbide hardening layer.

Titanium is a widely used metal, due to its light weight, higher strength than aluminum alloy, can maintain a higher strength than aluminum at high temperature and is highly valued by the aviation industry. Titanium has a wide range of uses in the military industry. Nuclear powered submarines, hydrofoil boats, anti-tank missiles, missile launchers, bulletproof vests, etc. In the aviation industry, civilian aircraft, strategic rocket engines, spacecraft satellite antennas and other large amounts of titanium.The presence of impurities in titanium significantly affects the physical, chemical, mechanical properties and corrosion resistance of titanium. In particular, some interstitial impurities can distort the crystal lattice of titanium and affect various properties of titanium.The good mechanical properties of titanium as a structural material are achieved by strictly controlling the appropriate impurity content and adding alloying elements.

Main advantages

- Low Density and High Specification Strength

- Customer request customization

- Excellent Corrosion Resistance

- Good Resistance to Effect of Heat

- Excellent Bearing to Cryogenics Property

- Good Thermal Properties

- Low Modulus of Elasticity