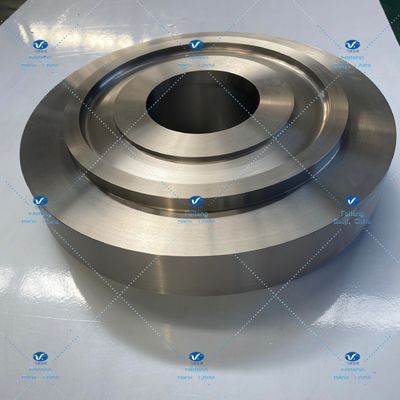

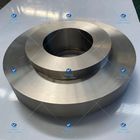

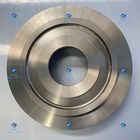

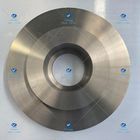

Feiteng Gr2 ASTM B381 Titanium Rings Fasteners

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

| Model Number | Titanium Fasteners |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Certification | GB/T19001-2016 Idt ISO9001:2015 GJB9001C-2017 | Material | Titanium |

|---|---|---|---|

| Packaging | Wooden Case | Model NO. | ASTM B381 |

| Item Name | Titanium Rings | Origin | Baoji, Shaanxi, China |

| Grade | Gr2 | Port Of Delivery | Xi'an Port, Beijing Port, Shanghai Port, Guangzhou Port, Shenzhen Port |

| Highlight | ASTM B381 Titanium Rings Fasteners,Feiteng Gr2 Titanium Rings Fasteners,ASTM B381 Titanium Fastener ring |

||

Titanium Rings Titanium Fasteners Gr2 ASTM B381 The Private Ordering Forged

|

Item Name |

Titanium Rings |

|

Grade |

Gr2 |

|

Material |

Titanium |

|

Certification |

GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

|

Port of delivery |

Xi'an port, Beijing port, Shanghai port, Guangzhou port, Shenzhen port |

The properties of titanium are closely related to temperature, morphology and purity. Dense titanium is fairly stable in nature, but powder titanium can cause spontaneous combustion in air. The presence of impurities in titanium significantly affects the physical, chemical, mechanical properties and corrosion resistance of titanium. In particular, some interstitial impurities can distort the crystal lattice of titanium and affect various properties of titanium.The properties of titanium are closely related to temperature, morphology and purity. Dense titanium is fairly stable in nature, but powder titanium can cause spontaneous combustion in air. The presence of impurities in titanium significantly affects the physical, chemical, mechanical properties and corrosion resistance of titanium. In particular, some interstitial impurities can distort the crystal lattice of titanium and affect various properties of titanium.The smelting process of titanium is generally carried out at a high temperature above 800℃, so it must be operated in a vacuum or under the protection of an inert atmosphere.

Forgings can be divided into cold forging, warm forging and hot forging according to the temperature of billet during processing. Cold forging is generally processed at room temperature, while hot forging is processed at a higher recrystallization temperature than the metal billet. The forging process and the die design are obviously different due to the difference of the structure complexity of the forgings. It is necessary to make clear the structure type of the forgings for the process design.

Forging can change the mechanical properties of a metal blank by applying pressure to it to produce a plastic deformation. The looseness of a metal can be eliminated by forging. The mechanical properties of the forgings can be improved. [2] Forging has the following uses:

Main advantages

- Low Density and High Specification Strength

- Customer request customization

- Excellent Corrosion Resistance

- Good Resistance to Effect of Heat

- Excellent Bearing to Cryogenics Property

- Good Thermal Properties

- Low Modulus of Elasticity