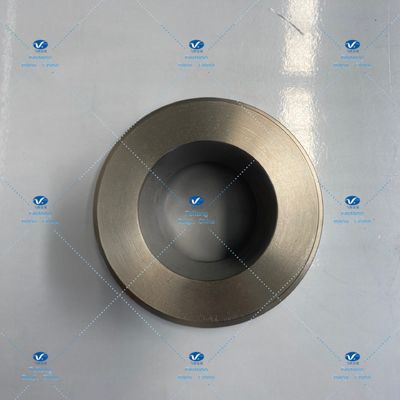

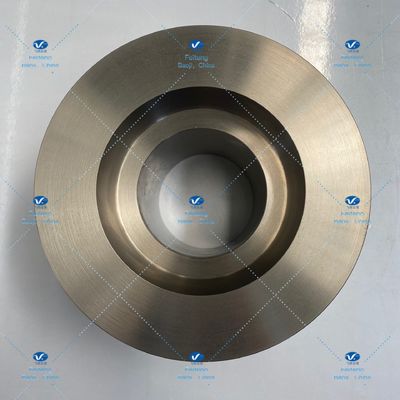

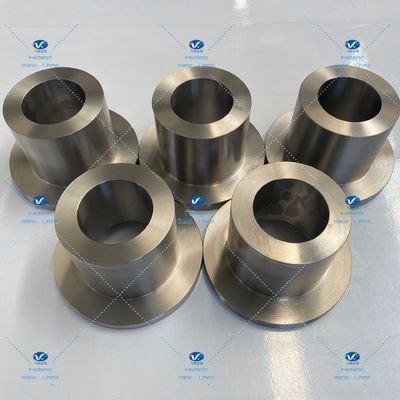

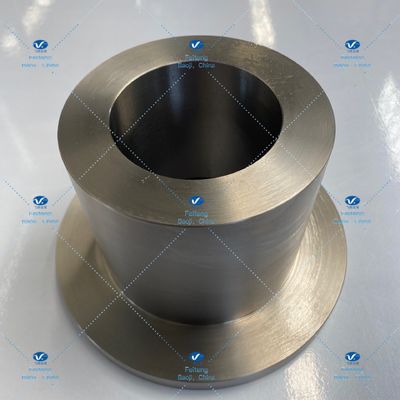

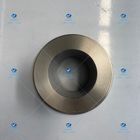

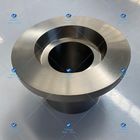

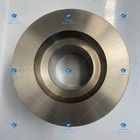

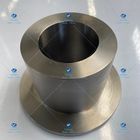

Gr12 Titanium Valve Seat ASTM B348 Titanium Rings

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

| Model Number | Titanium Valve Seat |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Packaging | Wooden Case | Certification | GB/T19001-2016 Idt ISO9001:2015 GJB9001C-2017 |

|---|---|---|---|

| Material | Titanium Alloy | Item Name | Valve Seat |

| Origin | Baoji, Shaanxi, China | Grade | Gr12 |

| Port Of Delivery | Xi'an Port, Beijing Port, Shanghai Port, Guangzhou Port, Shenzhen Port | Technique | Forging |

| Highlight | ASTM B348 Titanium Rings,Gr12 ASTM Titanium Rings,Gr12 Titanium Valve Seat |

||

Titanium Valve Seat Gr12 ASTM B348 The Private Ordering Titanium Rings

| Grade | Gr12 |

| Technique | Forging |

| Packaging | Wooden case |

| Port of delivery | Xi'an port, Beijing port, Shanghai port, Guangzhou port, Shenzhen port |

The valve seat is a detachable part inside the valve, which is used to support the valve core's full clearance and form a sealing pair. Generally, the valve seat diameter is the maximum flow diameter of the valve. For example, the valve seat materials of butterfly valves are very wide, and all kinds of rubber, plastic and metal materials can be used as valve seat materials.

The valve seat uses elastic sealing material and small actuating mechanism to obtain the bubble tight level seal. The compression seat sealing stress causes the material to be elastically deformed and squeezed into the rough surface of the metal parts to be used to block all the leakage paths. The permeability of the material is the basis for a small amount of leakage to the fluid.

Materials are too soft, or cold deformation (creep) occurs under load. They can be filled with filler, such as glass fiber, to harden them. If it is used to make thin sheets, it can still meet the requirements of use and eliminate cold deformation or permanent deformation.

The seal must be carefully fixed to prevent rupture and air leakage due to differential pressure. Soft valve seat bonding to metal parts is a method, but it can not completely solve the problem, because the bonding will break and fail when subjected to thermal shock. A sufficiently large pressure drop will destroy the bonding material.

Characteristic:

1) Good fluid compatibility, including expansion, hardness loss, permeability and degradation;

2) High hardness;

3) Permanent deformation;

4) The degree of recovery after load removal;

5) Pulping and compression strength;

6) Deformation before fracture;

7) Elastic modulus.