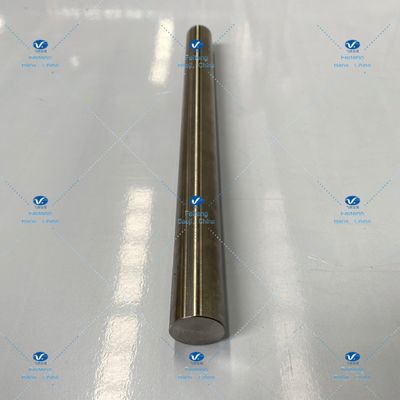

Gr5 25OD*317 High Mechanical Strength Titanium Bars

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

| Model Number | Titanium Bars |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Application | Industrial,Medical,exhaust Hanger,chemical,Condenser | Advantage | Light Quality,High Strengthen Anticorrossive,Corrosion Resistance,acid And Base Resistance |

|---|---|---|---|

| Package | Wooden Case | Name | Titanium Bars |

| Size | φ25*317 | Grade | Gr5 |

| Certification | GB/T19001-2016 Idt ISO9001:2015; GJB9001C-2017 | Place | Baoji, Shaanxi, China |

| Highlight | 25OD*317 Titanium Bars,Gr5 Titanium Bars,High Mechanical Strength Titanium rod |

||

Titanium Bars Gr5 ASTM B348-06 a 25OD*317 Titanium Products Titanium Round Rod Titanium Forging

|

Name |

Titanium Bars |

|

Grade |

Gr5 |

|

Transport Package |

Wooden case |

|

Origin |

Baoji, Shaanxi, China |

|

Port of delivery |

Xi'an port, Beijing port, Shanghai port, Guangzhou port, Shenzhen port |

| Shape | Round |

Titanium bar has high strength, good weldability and corrosion resistance. They are commonly used as heat and corrosion resistant materials. Titanium alloy is widely used in various fields because of its high specific strength, good corrosion resistance and high heat resistance. Since 1948, the demand of the aviation industry has allowed the titanium industry to grow at a rate of about 8% a year. At present, the annual output of international titanium alloy processing materials has reached 4 million tons. Titanium is mainly used in aero-engine compressor components, rocket, missile and high-speed aircraft layout components. By the mid-1960s, titanium and its alloys had been used in general industry, as electrodes in electrolysis industry, in power station condensers, in petroleum refining and desalination heaters, and in environmental pollution control equipment. Titanium and its alloys have become corrosion resistant.

Titanium alloy is a new important layout information applied in aerospace industry. Its specific gravity, strength and application temperature between aluminium and steel, but the specific strength is high, with excellent seawater corrosion resistance and ultra-low temperature function. The amount of titanium alloy used in aero-engine usually accounts for 20% ~ 30% of the total weight of titanium alloy. Mainly used for the manufacture of compressor components, such as cast titanium fan, compressor plate and blade, cast titanium compressor housing, intermediate housing, bearing seat, etc. The spacecraft is mainly made of titanium alloy with high specific strength, corrosion resistance and low temperature resistance. It produces various pressure vessels, fuel tanks, fasteners, instrument ties, frames, rocket shells, etc. Artificial earth satellites, lunar modules, manned spacecraft and space shuttles are also welded with titanium plates.

1, handling and loading convenience

2, strong corrosion resistance

3, the fluid resistance is small

4, high mechanical strength