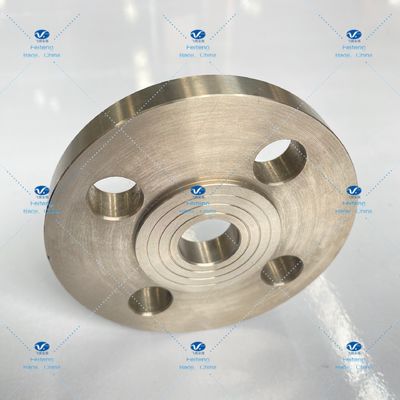

ASTM B348 Gr2 DN15 Slip On Titanium Flanges Threaded Socket Welding Flange

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

| Model Number | Titanium Flanges |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Marterial | Titanium | Transport Package | Wooden Case |

|---|---|---|---|

| Origin | Baoji, Shaanxi, China | Certification | GB/T19001-2016 Idt ISO9001:2015 GJB9001C-2017 |

| Company | Feiteng | Model NO. | Slip On Flange |

| Highlight | Gr2 DN15 Titanium Flanges,ASTM B348 Titanium Flanges,Gr2 Threaded Socket Welding Flange |

||

Titanium Flanges Gr2 DN15 Slip-On Flange Welding Neck Flange Blind Flange Socket Welding Flange Threaded Flange

| Item name | Titanium Flanges |

| Grade | Gr2 |

| Material | Titanium |

| Standard | ASTM B348 |

| Packaging | Wooden case |

| Port of delivery | Beijing port, Xi 'an port, Shanghai port, Shenzhen port etc. |

Slip-On Flange is a type of flange connected with a container or pipe by fillet weld. At the same time, there are two kinds of flange ring with neck and without neck. Compared with the butt welding flange with neck, flat welding flange structure is simple, the material is less, but the stiffness and sealing than the butt welding flange with neck. Flat welded flanges are widely used in the connection of medium and low pressure vessels and pipelines. The sealing principle of flat welded flange is that the two sealing surfaces of the bolt squeeze the flange gasket and form a seal, but this also leads to the destruction of the seal. To maintain the seal, you have to maintain a huge bolt force, and to do that, you have to make the bolt even bigger. Larger bolts need to match larger nuts, which means larger diameter bolts are needed to create the conditions for tightening the nut. However, the larger the diameter of the bolt, the applicable flange will become bent, the only way to increase the thickness of the flange part of the wall. The entire installation will require enormous size and weight, which is a particular problem in offshore environments, where weight is always a major concern. And, fundamentally, a flat-welded flange is an ineffective seal that requires 50 percent of the bolt load to be used to squeeze the gasket and only 50 percent of the load to hold the pressure.

Product advantage

1, Strong corrosion resistance

2, Handling and loading convenience

3, The fluid resistance is small

4, High mechanical strength