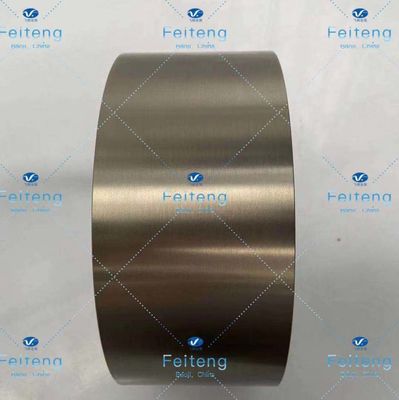

2.2KG Gr2 194OD*174ID*81THK Titanium Forged Rings ASTM B381

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

| Model Number | Titanium Rings |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

| Item Name | Titanium Rings | Material | Titanium Alloy |

|---|---|---|---|

| Size | φ194*φ174*81 | Weight | 2.2KG |

| Origin | Baoji, Shaanxi, China | Packaging | Wooden Case |

| Specification | ASTM B381 | Certification | GB/T19001-2016 Idt ISO9001:2015; GJB9001C-2017 |

| Highlight | 174ID Titanium Forged Rings,2.2KG Titanium Forged Rings,Titanium Forged Rings ASTM B381 |

||

Titanium Rings Gr2 ASTM B381 194OD*174ID*81THK Titanium Processing Titanium Forged

|

Item Name |

Titanium Rings |

| Grade | Gr2 |

|

Material |

Titanium |

|

Standard |

ASTM B381 |

|

Size |

φ194*φ174*81 |

| Origin | Baoji, Shaanxi, China |

The good mechanical properties of titanium ring are achieved by strictly controlling the appropriate impurity content and adding alloying elements. Titanium ring with high specific strength, good mechanical properties and good corrosion resistance has become an ideal material for aircraft and engines. In recent years, titanium alloy has been widely used in the manufacture of compressor section, engine hood, exhaust device and other structural frame parts of aircraft engines. Titanium processing industry is developing fast at present, it not only with many of the good qualities of titanium industry made a lot of love, and also have sophisticated metal plastic working skills to be able to use, which has a long history of steel and non-ferrous metals processing skills and equipment to be able to use and learn about, this makes the plasticity of titanium processing skills, able to quickly improve and sophisticated. Now titanium and titanium alloy are widely used in deep submersible, icebreaker, hydrofoil, hovercraft, minesweeper, propeller, whip antenna, seawater pipeline, condenser, heat exchanger, petroleum equipment, chemical equipment, sports equipment, automobile manufacturing, medical equipment, tools and so on. Mainly using its excellent corrosion resistance, and low density, memory, non-magnetic.

Advantages and applications:

1, low density can reduce the weight of the vehicle, for high-speed moving parts, can reduce the motion inertia;

2, high specific strength can be used as load-bearing parts;

3, small elastic modulus, anti fatigue strength;

4, good heat resistance, suitable for high temperature parts;

5, small thermal expansion coefficient, suitable for engine valve and other components;

6, good corrosion resistance

7, good frost resistance, will not produce low temperature brittleness;

8, good formability, can be made by stamping, hot forging, powder metallurgy, precision casting and other methods of various shapes of parts;

9, decorative, through oxidation treatment, can form a variety of colorful decorative materials