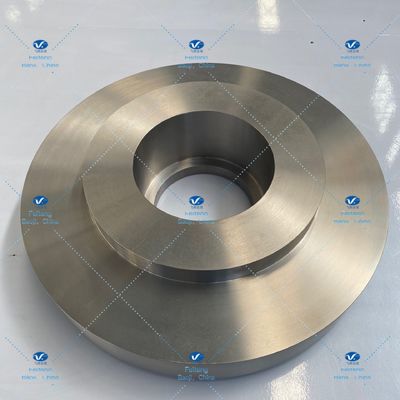

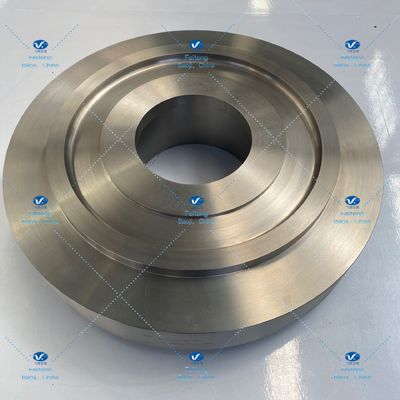

ODM GJB9001C Gr2 ASTM B381 Forged Titanium Rings

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

| Model Number | Titanium Fasteners |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

| Packaging | Wooden Case | Certification | GB/T19001-2016 Idt ISO9001:2015 GJB9001C-2017 |

|---|---|---|---|

| Material | Titanium | Item Name | Titanium Rings |

| Model NO. | ASTM B381 | Origin | Baoji, Shaanxi, China |

| Grade | Gr2 | Port Of Delivery | Xi'an Port, Beijing Port, Shanghai Port, Guangzhou Port, Shenzhen Port |

| Highlight | ASTM B381 Forged Titanium Rings,GJB9001C Titanium Rings,ODM Gr2 Titanium valve Ring |

||

Titanium Rings Gr2 ASTM B381 The Private Ordering Titanium Forged

|

Item Name |

Titanium Rings |

|

Grade |

Gr2 |

|

Material |

Titanium |

|

Certification |

GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

|

Port of delivery |

Xi'an port, Beijing port, Shanghai port, Guangzhou port, Shenzhen port |

Forgings can be divided into cold forging, warm forging and hot forging according to the temperature of billet during processing. Cold forging is generally processed at room temperature, while hot forging is processed at a higher recrystallization temperature than the metal billet. The forging process and the die design are obviously different due to the difference of the structure complexity of the forgings. It is necessary to make clear the structure type of the forgings for the process design.

Forging can change the mechanical properties of a metal blank by applying pressure to it to produce a plastic deformation. The looseness of a metal can be eliminated by forging. The mechanical properties of the forgings can be improved. [2] Forging has the following uses:

(1) General industrial forgings refer to machine tool manufacturing, agricultural machinery, agricultural tool manufacturing and bearing industry and other civil industries.

Forgings for hydro generator, such as main shaft and intermediate shaft, etc.

(3) Forgings for thermal power stations, such as rotor, impeller, retaining ring spindle, etc.

(4) Metallurgical machinery, such as cold roll, hot roll and herringbone gear shaft.

Forgings for pressure vessels, such as cylinder, cauldron flange and sealing head.

Marine forgings, such as crankshaft, stern shaft, rudder, thrust shaft and intermediate shaft, etc.

⑦ Forging machinery and equipment, such as hammer, hammer rod, hydraulic press column, cylinder, axle press machine pillar and cylinder, etc.

Module forgings, mainly for hot die forging hammer forging die.

9 automobile industry forgings, such as left and right knuckle, front beam, coupler, etc., according to statistics in the automobile, forgings account for 80% of its mass.

⑩ forgings for locomotives, such as axles, wheels, leaf springs, crankshafts of locomotives, etc. According to statistics, forgings account for 60% of the mass of locomotives.

According to statistics, forgings for military use, such as gun barrel, door body, gun latch support and traction ring, account for 65% of the mass of a tank.

Features:

1) Wide range of weight. Forgings range from a few grams to hundreds of tons

2) Higher quality than casting. The mechanical properties of forgings are better than those of castings, which can withstand large impact force and other heavy loads. Therefore, some important parts with large forces are used for forgings.

Forgings are of better quality than rolled steel for high carbide steel. For example, the high speed steel rolling material can only meet the use requirements after modification and forging. In particular, HSS milling cutters must be reformed.

3) The lightest. On the premise of ensuring the design strength, the weight of the forgings is lighter than that of the castings, which reduces the weight of the machine itself, which is of great significance to the vehicles, aircraft, vehicles and airborne lifting equipment.

4) Saving raw materials. For example, when the crankshaft with a static weight of 17 kg is used in the car, the chip takes up 189% of the weight of the crankshaft when the rolling cutting forging is adopted, while the chip takes up only 30% when the die forging is adopted, and the machining time is shortened by 1/6.

Precision forging forgings can not only save more raw materials, but also save more machining hours.

5) High productivity. For example, 30 automatic cutting machines can be replaced by two hot die forging press die forging radial thrust bearings. The productivity of 6-axis automatic lathe is 17.5 times of M24 nut production by using push forging automaton.

6) Free forging is flexible, so forging is widely used in some repair factories to produce various accessories.