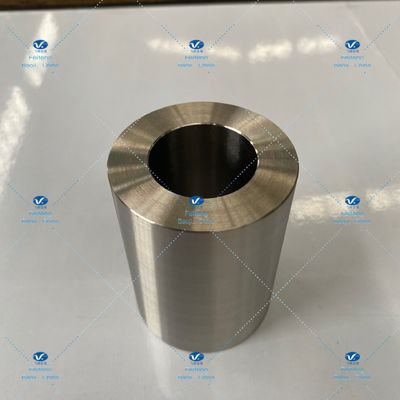

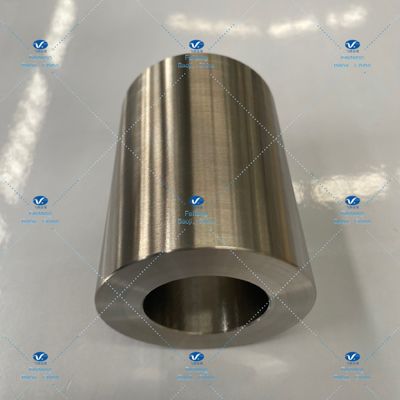

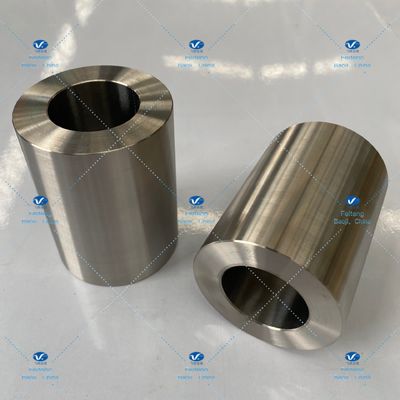

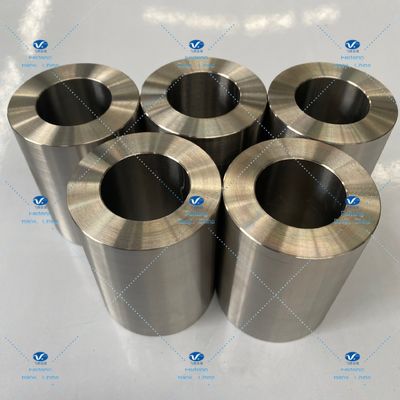

Gr2 ASTM B348 64OD*38ID*85THK Titanium Rings

| Place of Origin | Baoji, Shaanxi, China |

|---|---|

| Brand Name | Feiteng |

| Certification | GB/T19001-2016 idt ISO9001:2015 GJB9001C-2017 |

| Model Number | Titanium Ring |

| Minimum Order Quantity | To be negotiated |

| Price | To be negotiated |

| Packaging Details | Wooden case |

| Delivery Time | To be negotiated |

| Payment Terms | T/T |

| Supply Ability | To be negotiated |

| Brand Name | Feiteng | Model Numble | Titanium Ring |

|---|---|---|---|

| Grade | Gr2 | Certification | GB/T19001-2016 Idt ISO9001:2015 GJB9001C-2017 |

| Specification | ASTM B348 | Size | φ64*φ38*85 |

| Packaging | Woofen Case | Place Of Origin | Baoji, Shaanxi, China |

| High Light | 85THK Titanium Rings,38ID Titanium Rings,Gr2 ASTM B348 Titanium Ring |

||

Titanium Rings Gr2 ASTM B348 64OD*38ID*85THK Titanium Processing Titanium Forged

|

Item Name |

Titanium Rings |

|

Grade |

Gr2 |

|

Standard |

ASTM B348 |

|

Size |

φ64*φ38*85 |

|

Test |

Ultrasonic testing |

|

Packaging |

Wooden case |

|

Port of delivery |

Xi'an port, Beijing port, Shanghai port, Guangzhou port, Shenzhen port |

Titanium has a metallic luster and ductility. Titanium is characterized by its low density, high mechanical strength and ease of processing. The plasticity of titanium depends largely on its purity. The purer the titanium, the more plastic it is. Good corrosion resistance, not affected by the atmosphere and seawater. At room temperature, it will not be corroded by hydrochloric acid below 7%, sulfuric acid below 5%, nitric acid, aqua regia or dilute alkali solution; Only hydrofluoric acid, concentrated hydrochloric acid, concentrated sulfuric acid can act on it. The presence of impurities in titanium greatly affects its mechanical properties, especially the interstitial impurities (oxygen, nitrogen, carbon) can greatly improve the strength of titanium and significantly reduce its plasticity. The good mechanical properties of titanium as a structural material are achieved by strictly controlling the appropriate impurity content and adding alloying elements.

As a structural material, titanium ring can obtain good mechanical properties by strictly controlling the appropriate impurity content and adding alloy elements. Titanium ring has the advantages of high specific strength, good mechanical properties and corrosion resistance. It is an ideal material for aircraft and engines. In recent years, with the development of machining technology, titanium alloy has been widely used in the manufacture of structural parts such as aeroengine compressor section, hood and exhaust device. At present, the titanium processing industry is developing rapidly. It not only has won a lot of love in the titanium industry with many excellent qualities, but also has exquisite metal plastic processing skills and can be used. Among them, the skills and equipment with a long history of steel and non-ferrous metal processing can be used and learned, which makes the plastic processing skills of titanium can be improved and improved rapidly. Titanium and titanium alloys are widely used in deep-sea submersibles, icebreaker, hydrofoil, air cushion vehicles, Minesweeper, propellers, whip antennas, seawater pipes, condensers, heat exchangers, petroleum equipment, chemical equipment, sports equipment, automobile manufacturing, medical equipment, tools and so on. It mainly uses its excellent corrosion resistance, low density, memory and non-magnetic.

Main advantages and applications:

1. Low density.

2. Higher than strength.

3. Small elastic modulus, high fatigue strength, suitable for spring;

4. Low coefficient of thermal expansion.

5. Good corrosion resistance.

6. Good formability.